Efficient Cooling Solutions for Sustainable Meat Alternatives

01/15/2025

In a world that is increasingly focusing on sustainability, the production of meat alternatives is playing an ever more important role. A customer project from the United Kingdom shows how JULABO is helping to achieve ecological and economic goals through innovative refrigeration technology.

Challenge: Reducing water consumption

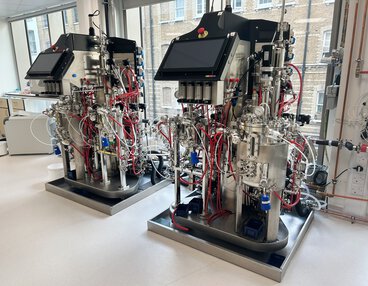

Our British customer is working on the design of cruelty-free, sustainable fats that are used for delicious meat alternatives together with plant-based proteins. However, the two Biostream Process Reactor systems used required large amounts of tap water for cooling. The aim was to minimize the environmental impact by switching to a more closed and resource-efficient cooling system.

The solution: The air-cooled FL1703 chiller

After a precise calculation of the previous water costs and consumption, it became clear: by switching to the FL1703 cooler from JULABO, the savings would pay for the investment in just over a year. This not only brings financial benefits, but also significantly reduces the impact on the environment.

The project began with a comprehensive analysis by the responsible JULABO Technical Sales Manager,

who carefully examined the situation on site. Not only were the existing cooling systems and their efficiency checked, but the specific requirements of the business were also recorded in detail.

In close cooperation with the customer, individual requirements and optimization potential were identified.

Based on the data and findings obtained, the JULABO team developed a tailor-made solution that sustainably reduces both energy consumption and operating costs.

Implementation: Perfect cooling for several reactors

The JULABO FL1703 cooler was connected to two Biostream Biotwin systems (dual reactors). In order to distribute the cooling capacity evenly to all four reactors, we used our specially developed quad distributing adapters. These ensure constant and controlled temperature regulation at all connections. The result is a stable and reliable cooling process that meets the customer's high requirements.

Sustainability and precision combined

- Significantly reduce water consumption.

- Save costs as the system is already economically viable after a short time.

- Minimize the environmental impact of unnecessary water consumption.

- At the same time ensure precise and reliable temperature control.

Conclusion

This project is another example of how JULABO is helping customers reduce their environmental impact while still warranting the highest precision and quality. Our innovative solutions make sustainable production possible - without compromising on performance.