Precise Flow Control for External Applications with Defined Volume Flow

10/26/2022

Even in the standard version, JULABO temperature control instruments are generally equipped with high-performance pumps that cover a variety of external applications via various pump stages. Nevertheless, there are applications that, in addition to precise temperature control, also require a precisely defined volume flow of the medium used. JULABO has developed and implemented numerous variants of customer-specific flow measurement and control systems for this challenge.

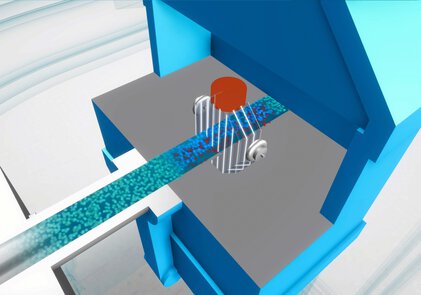

In addition to the mandatory flow meter, JULABO integrates all necessary components into one individually configured FlexiRack, which is either attached directly to the device or installed nearby. In terms of hardware and software, all components are optimally matched to each other and to the customer's application. This also includes selecting the ideal measuring principle for the application. Typically, one of the following two measuring principles is used with various advantages:

Both measuring principles are independent of the physical medium properties temperature, pressure, density and viscosity. This is a decisive advantage over other measuring principles, as these properties can change significantly over the temperature range.

Precise control thanks to flowmeter

If the external application requires a precisely defined volume flow, this can be achieved by means of a flow control system. The installed measuring device determines the current flow, transmits this information to the temperature control instrument, which regulates it to the desired setpoint value. The flow control therefore precisely ensures the desired energy transfer that is optimally suited to the application. This is particularly advantageous for sensitive processes and a test result as unadulterated as possible.

Typical application examples can be found in battery research, in test benches for component testing in the automotive industry or in the aerospace industry. However, the realization of several parallel temperature control circuits via just one process system is also possible with an adapted flow control system.

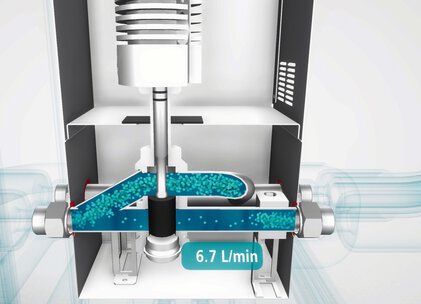

Flow control at low volume flows

Due to their physical function, some components of temperature control instruments require a certain minimum volume flow in order to be able to control the temperature at all. If the required flow of the customer application is below this minimum level, a flow control system with electronic bypass is used. The latter regulates the exact temperature control of the application with a defined flow and energy input, feeding the excess quantity of the medium directly back into the unit so that unnecessary power losses are minimized. The minimum volume flows are generally >5 l/min for smaller process systems (e.g. PRESTO A40 or A80) and >15 l/min for larger systems (e.g. PRESTO W55).

The electronic bypass is also useful if the back pressure of the application is too low at the desired flow (<0.07 bar) and thus offers high flexibility in the area of process temperature control for various application scenarios.

Reliable measurement and flow control in the temperature control process is no problem at JULABO

JULABO flow measurement and control systems enable users to optimally coordinate the medium flow, adapted to specific requirements. This means that applications with defined volume flow can be precisely, efficiently and reliably temperature-controlled – even with very low volume flows. They are usually used in conjunction with the process systems of the PRESTO series. Systems for recirculating coolers or laboratory circulators can also be adapted on request.

To the examplesPRESTO process systemsVideo Flow Control