Case Story >Battery Thermoregulation System< for Automotive

11/12/2024

Control Sistem is one of the leading Italian companies in the development of testing facility solutions for the automotive industry. For a project for a well-known European car manufacturer, they need an adequate temperature control system for their >Battery Thermoregulation System<.

Requirements for temperature control technology

The Battery Thermoregulation System (BTS) from Control Sistem is designed for automated thermal stress tests of battery cells. It simulates different temperatures within the battery cells by circulation of liquids within the cooling circuit of battery packs. With these tests, the car manufacturer can ensure that batteries operate within an optimal temperature range, which is crucial for maintaining performance, efficiency, and longevity.

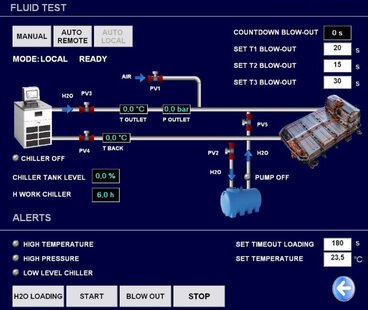

One main function of the automation system is the so-called blow out function. This procedure allows the fluids to be discharged by introducing compressed air into the circuit. The compressed air forces the liquids towards the hydraulic panel reservoir.

The BTS includes four main components: a panel PC, a PLC, a hydraulic panel and a chiller.

The chiller is required for precise control of the desired temperature within the battery cells. These temperature requirements for the battery cells range from +20 to +28 °C. In addition, an external pump with a maximum flow rate of 700 l/h is necessary to enable an adequate flow of the pure mineral-free water.

For efficient automation of the whole system, the chiller and all other components need to be integrated by Modbus TCP with an Ethernet interface.

Temperature control solution

After intensive discussions, Control Sistem decides to use 4 MAGIO MS-1000F for integration in their Battery Thermoregulation System at the car manufacturers side. The easy integration via Ethernet interface allows for optimum automation of all process functions like filling and blow out the cooling circuit of the batteries.

Umberto Bisceglia, Project Development at Control Sistem, is very satisfied with the result: “JULABO was very open-minded to deliver the ideal temperature control unit for our Battery Thermoregulation System. Together, we found the best solution and our customer is now very happy with the result. They have already executed hundreds of battery cell tests with precise and reliable results.”

Short info about Control Sistem S.r.L.

Control Sistem is an Italian company specializing in the design, production, and installation of advanced automation and control systems, especially for the automotive business. With a focus on industrial applications, they provide customized solutions for optimizing manufacturing processes, improving efficiency, and ensuring safety. Their expertise spans across various industries, offering innovative technologies such as PLC systems, SCADA software, and integrated monitoring solutions.

Short info about JULABO

JULABO GmbH, founded in 1967 in Germany, develops sophisticated temperature control technology and stands for innovation and competence in this area. Our units equipped with state-of-the-art control technology are used, when highest temperature accuracy or fastest response to temperature changes are important. More than 600,000 JULABO units installed worldwide demonstrate the high acceptance among users in research and industry. With proven quality “Made in Germany” and fast and competent service by local contact partners, JULABO has developed to a leading premium brand for temperature control solutions.