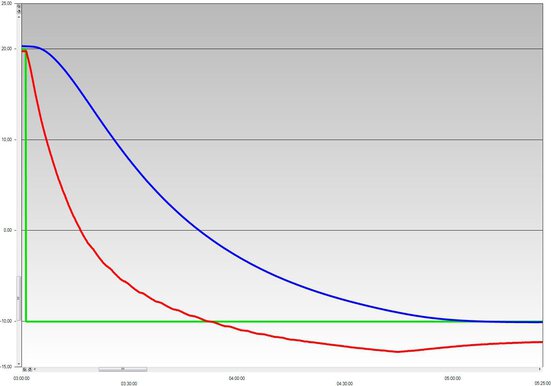

Case Study: PRESTO A30 Process system

Cooling a QVF 6 l reactor from +20 °C to -10 °C with a PRESTO A30 Process system

Objective

This case study tests the cooling capacity of the JULABO PRESTO A30 Process system with a 6 l glass reactor. The PRESTO A30 is connected to the reactor via two 2 m long metal hoses. The PRESTO A30 Process system has been programmed to cool down from +20 °C to -10 °C.

Test Conditions

| Product | PRESTO A30 Process system |

|---|---|

| Heating capacity | 2.7 kW |

| Pump pressure | 0.5 bar |

| Duration | 2:00 hr:min |

| Test volume | 5 l |

| Setpoint 1 | +20 °C |

| Setpoint 2 | -10 °C |

| Reactor | 6l QVF (glass) |

| Tubing length | 2 m |

| Fluid in unit | Thermal HL60 |

| Fluid in reactor | Thermal HL60 |

Environment

| Room temperature | 20 °C |

|---|---|

| Humidity | 45 % |

| Voltage version | 230V/50Hz |