One-Stop Solution With Temperature Control Technology for Bayer

04/14/2022

The Bayer AG Crop Science division researches and develops new plant protection products at the Monheim site in Germany. In order to expand the capacities for post-synthesis in the kilogram range, a new building has been built that doubles the existing laboratory space. In future, the laboratories will use, among other things, various reactor types from 0.5 to 30 liters for syntheses, for which high-precision temperature control from -85 °C to 160 °C is an essential component.

Requirements from Bayer

Bayer would ideally like to rely on one provider for the complete temperature control technology for the new laboratory in order to have a competent contact person who can react quickly and effectively, for example in the event of special requirements or in the event of maintenance and service. Based on positive experiences with various circulators, JULABO is also represented in the shortlist of suppliers.

The new laboratory building of the Bayer AG Crop Science division

The performance data for the various reactors and use cases differ for each order. One of the main criteria for the selection of the technology is therefore the greatest possible flexibility of the individual units. They need enough power reserve in order to be able to respond to individual customer requests (30 liter reactor, -85 °C to -75 °C). Another important point is the general safety concept of the technology used, as Bayer places the highest priority on the safety of both processes and its employees. Part of this includes correspondingly planned maintenance and service intervals, which include, for example, a test of the pressure sensors and regular leak tests as part of the F-Gas Regulation.

Other topics such as acoustic power levels, space requirements in the laboratory, controllable analog interfacers or the possibility of limiting pressure to max. 3 bar for the reflux condensers are part of the package of requirements.

The JULABO solution approach

JULABO works closely with Bayer to create a complete package with two instrument series for the various applications.

Several recirculating coolers with analog connection type SC5000w are used. They are used for the reflux condensers, where the core features of robustness and longevity play a decisive role.

For the larger reactors, JULABO supplies various water-cooled models of the highly dynamic temperature control systems PRESTO. From the smaller W40 to the compact mid-range W85 and the most powerful W91 units. With these process circulators, Bayer has the required wide range of applications and the greatest possible flexibility. The W91 even provides power reserves for currently unknown applications that may be required in the future.

All units have a suitable safety concept to meet the strict requirements from Bayer. In addition, a maintenance and service contract is agreed in order to be able to ensure a fast response time at all times and thus a high level of reliability during ongoing operation.

To ensure the smoothest possible start, the units were installed and commissioned cooperatively by Bayer and JULABO service experts at the Monheim site.

Performance under real conditions

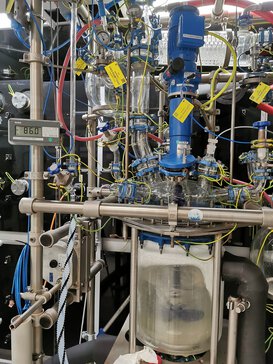

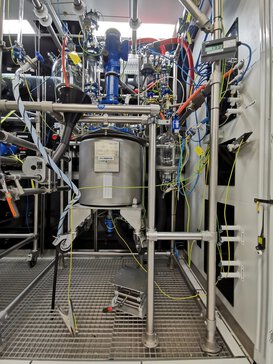

The pictures below show a 30 liter glass reactor at -86 °C and an Alloy59 reactor at -88 °C. The advantage is that the temperature in the glass reactor rises to -85°C during dosing but there is no change in the Alloy59 reactor. The actual reaction temperatures are -80 °C.

The temperature control instruments from JULABO are located in adjoining rooms and the fume hoods are therefore built so that the reactors can be supplied with core drill holes. All units are water-cooled and are spread over one large and two small equipment rooms. The big advantage here is that there are no restrictions in these rooms, for example for soldering or welding work. This means that maintenance or repair work can be carried out directly on site and ongoing work in the reactor areas can continue undisturbed.

Conclusion

Thanks to close cooperation and coordination in every project phase, the initial Bayer requirements were met to the fullest satisfaction. With the help of the new JULABO temperature control instruments, Bayer carries out various post-synthesis operations in the kilogram range and still has power reserves for possible further applications in the future. Horst-Erwin Bitasch, responsible Lab Technician Chemistry at Bayer Crop Science, is satisfied with the result: "The temperature control instruments run reliably and as expected, even over several days in continuous operation. And if something does happen, JULABO service colleagues are available to help very quickly. For me, that's a true partnership."

Short info about Bayer Crop Science

Ingenuity is the engine that drives human progress. It sparks breakthroughs needed to address the world’s biggest challenges and makes the unimaginable possible. At Bayer, we believe in the power of human ingenuity to shape one of humankind’s first inventions: agriculture. For more than 150 years, we’ve used science and imagination to help better people’s lives by advancing health and nutrition. And together, we can achieve so much more.

We’re committed to a better world. A world in which biodiversity thrives in harmony with humankind. Hunger and climate change are terms relegated to history books. Farms are more sustainable, with plants that are more adaptive and resilient. Agriculture increases economic prosperity for all families and their communities.

Working together, we can make agriculture part of the solution. We have the opportunity and the responsibility to grasp this moment and help move humanity forward by tirelessly shaping what’s possible.

Short info about JULABO

JULABO GmbH, founded in 1967 in Germany, develops sophisticated temperature control technology and stands for innovation and competence in this area. Our units equipped with state-of-the-art control technology are used, when highest temperature accuracy or fastest response to temperature changes are important. More than 600,000 JULABO units installed worldwide demonstrate the high acceptance among users in research and industry. With proven quality “Made in Germany” and fast and competent service by local contact partners, JULABO has developed to a leading premium brand for temperature control solutions.