Seeking Premium Temperature Control for Your Aerospace Material Testing?

JULABO offers you a free test unit from its state-of-the-art PRESTO series

Precise temperature control is essential for aerospace applications, where components and materials must undergo rigorous testing to evaluate their suitability under extreme pressure and temperature conditions. "PRESTO, JULABO's highly dynamic temperature control system, is the preferred choice for many aerospace developers and quality testers due to its precision and robust performance", emphasizes Neil Brown, JULABO's sales manager specializing in aerospace markets.

Contact us now to experience JULABO's high precision:

Test a PRESTO unit for free under the real conditions of your testing application.

Contact Us for a Free Trial:

What Is the PRESTO System Offering?

The PRESTO systems are designed for precise temperature control as well as rapid temperature changes, making them ideal for reactor vessels, material stress tests, or temperature simulations. These instruments cover a working temperature of -93 to +250 °C with high cooling and heating capacity.

Highly efficient components give these instruments the ability to compensate for exothermic and endothermic reactions with extraordinary speed. Permanent internal monitoring and self-lubricating pumps contribute to the PRESTO’s long service life. The integrated 5.7-inch color industrial-grade touch panel gives the user a clear and well-organized view of important information while greatly improving user-friendliness. Once in operation, the new PRESTO units are whisper quiet and barely audible in a laboratory. PRESTO units are extremely robust and work reliably even if the ambient temperature climbs as high as +40 °C. Multiple interfaces permit remote control of the PRESTO across networks and in superordinated control systems. Closed side panels without ventilation slits reduces to a minimum the amount of space needed to operate.

PRESTO SystemsCase Story: Tailored Solution for Aviation

The customer's requirements included simulating and maintaining a constant temperature in a pilot's cockpit. The intention was to test the behavior of the inserted glass under various realistic scenarios. A tailor-made heat exchanger with piping and connections was designed and implemented because a high heat transfer rate had to be realized in the smallest possible space. This means that the connected PRESTO W50 can optimally transfer its full power to the application.

Learn about our customized solutionsTemperature Control for Aerospace

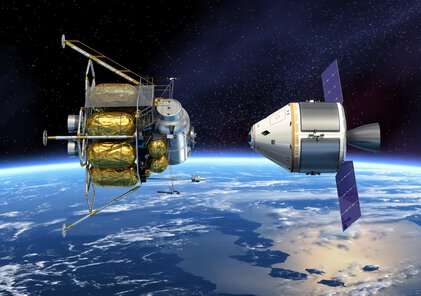

In the realm of space exploration, satellites are essential for global communication and various services. However, their effectiveness depends on overcoming challenges posed by extreme temperature variations in the vacuum of space. With over 2,000 operational satellites in orbit, ensuring their resilience against harsh conditions is paramount. Satellites encounter significant temperature differentials between the sunlit and shaded sides of celestial

bodies, necessitating rigorous testing for resilience and thermal stability under extreme conditions. The objective is clear: these satellites must endure harsh temperature challenges prevalent in space. Crucial to global communication, these satellites demand materials resilient to the vacuum of space and temperature extremes. Intricate engineering ensures longevity and reliability in the face of challenging conditions.

Satellites and the Conditions Under Which They Must Work

A primary concern in satellite development is addressing risks associated with overheating and cold-related failures. To manage temperatures effectively in space, engineers deploy strategies involving specialized outer materials, rotation mechanisms, and booster heaters. These mechanisms contribute to maintaining optimal operating conditions for internal components. Given the impracticality of maintenance or repair in space, satellites undergo extensive testing to simulate space conditions. Thermal vacuum chambers play a crucial role in subjecting satellites to the harsh environment they will operate in, ensuring they can withstand the challenges they will encounter. In essence, satellite development involves meticulous processes focusing on advanced technologies and systems, along with the ability to withstand unforgiving temperature conditions. As we look toward the future of space exploration, the resilience of satellites to extreme temperatures remains a cornerstone of their operational success.