Temperature simulation for quality assessment of batteries

E-mobility is one of the global megatrends

E-mobility is one of the global megatrends and is currently fundamentally changing many areas of the automotive industry. In the field of e-mobility, in addition to charging stations and electric motors, research and development activities are currently focused on batteries and their charging capacity.

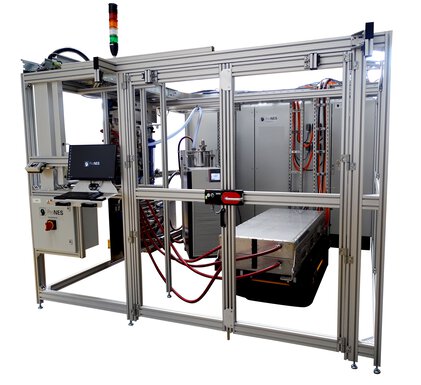

ProNES automation GmbH is a specialist in customer-specific automation in testing and measuring technology and supplies automotive suppliers with automation solutions from a single source. The all-in-one battery inspector, which has proven itself in 24/7 operation for years, offers a battery-specific, diverse range of QA and safety functions. The "batterieinspektor" ensures that powerful and safe batteries can be manufactured in forward-looking smart factories. Precise temperature control of fluids is crucial for various testing and quality assurance functions of the system. This means that, for example in endurance tests, ambient conditions with changing temperatures can be simulated as realistically as possible.

Requirements for temperature control technology

ProNES customers expect complete system solutions from a single source. The "batterieinspektor" can be used to check the quality and functionality of batteries in electric vehicles under real conditions. For the comprehensive tests it is necessary to set different temperatures. In view of the range of functions, ProNES opted for a JULABO temperature control system.

A water-glycol mixture is used as temperature control medium and is used in the same form in the cooling circuit of the vehicles. The temperature range in the test processes is normally within a manageable range of +22.5°C to +45°C. In addition, the temperature control system must provide sufficient power at all times in order to be able to quickly and precisely compensate for dynamic temperature fluctuations. The minimum requirements for the compact temperature control system are 9 kW heating capacity and 2 kW cooling capacity, as well as a powerful pump, which meets the required pressure of approx. 2 bar.

In addition, the test bench requires suitable interfaces to the JULABO temperature control system used in order to be able to be integrated into the test processes. An RS232 or Ethernet interface for logging is required for control.

At the same time, the system requires a separate, external reservoir as a buffer for the bath fluid. If optimally designed, this ensures that the test specimens are filled and blown out smoothly.

The JULABO solution approach

The PRESTO A45t process system easily meets the basic requirements of ProNES in terms of performance data and interfaces. In addition, the experts at JULABO modify the temperature control system individually for integration into the "batterieinspektor".

The special solution includes a special rack for the PRESTO A45t. The required 60-litre reservoir for filling and blowing out including level detection and the corresponding connections is positioned in this. In addition, shut-off valves for quick disconnection of the system, an air separator for continuous deaeration and a manual bypass are integrated. The bypass keeps the content of the tank constant at the target temperature while the test specimens are being changed. This eliminates unnecessary times for reheating and cooling. Together with the PRESTO A45t, the special rack forms a flexible and mobile unit.

Conclusion

Thanks to the perfect integration of the PRESTO A45t process system including special rack, ProNES can offer its customers the fully automated "batterieinspektor" from a single source. In the meantime, several test benches have proven themselves under real-life conditions in the quality assurance of batteries, among other things in the USA.

Max Schultz, Project Manager at ProNES, draws a positive conclusion from the cooperation with JULABO: "The cooperation with JULABO is very professional and expedient. We are happy to be able to implement our solution with this reliable partner."

The most important basis for the successful realization of the project was the open, constructive exchange at every project phase. In just a few months, JULABO was able to develop and build a special solution that meets all the requirements of ProNES and its customers.

Short info about ProNES

ProNES automation GmbH stands for customer-specific automation in measurement and testing technology. The requirements of the diverse customer spectrum as well as the many years of know-how form the framework for precise development and the integration of tailor-made hardware and software. The innovative "batterieinspektor" is an example of the complex measurement technology solutions. The complete solutions are developed with the focus on seamlessly integrating them into comprehensive automation systems, planning projects in a customer-oriented and professional manner, and implementing them transparently.