Case Stories and Applications

JULABO offers an outstanding quality standard and guarantees high customer satisfaction. The convincing performance data of the highly dynamic temperature control systems means extremely short heat-up and cool-down times, and scores with a very wide working temperature range without changing the heat medium. The development of customer-specific solutions makes it possible to use JULABO temperature control instruments in any industry for almost all applications.

Temperature control systems in action: Cannabis extraction

The sale of cannabis products is increasing and requires efficient extraction and refining processes. Numerous end products are currently available on the market - from the raw extract in different consistencies to the crystalline or the dissolved pure substance. The breadth of the possible administration forms is reflected in the multiplicity of processing methods. These require sophisticated temperature management that is perfectly adapted to the respective requirements.

Cannabis extractionCustom solution for Schaeffler: Temperature simulation for e-mobility

Automotive suppliers are reacting to the greater susceptibility that electric drives have to failure when compared to combustion engines by carrying out tests under extreme temperature conditions. After intensive cooperation with the automotive and industrial supplier Schaeffler, we created a custom solution for the temperature control of a universal test chamber in which the test specimens can be placed in precisely simulated ambient and extreme temperatures during endurance and functional testing.

Quality test of separating clutchesMaterial tests in the automotive industry

Material, construction or processing defects can lead to serious safety issues for road users. Quality assurance requirements for automotive suppliers are therefore extremely strict. The testing methods used must include temperature fluctuations that mimic what the cars will be subject to in actual use. These are determined by both the environmental conditions and also the operating temperature. Precise temperature management is therefore very important to the test benches in the automotive and automotive supplier industry.

Material and component testsTemperature simulation for quality assessment of batteries

E-mobility is one of the global megatrends and is currently fundamentally changing many areas of the automotive industry. In the field of e-mobility, in addition to charging stations and electric motors, research and development activities are currently focused on batteries and their charging capacity.

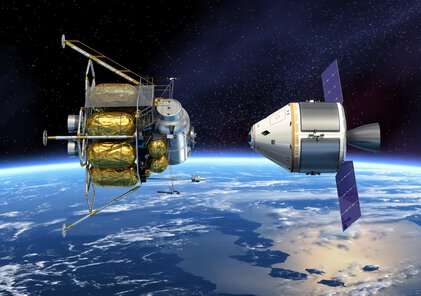

Quality assessment of batteriesTemperature control of satellite tests

The temperature differences that satellites are subject to in space are immense. Depending on the orbit, temperatures range from +150 °C on the sunny side and -190 °C on the dark side of the earth. Because maintenance or repair is not possible, all the materials and components, as well as the satellite itself, need to undergo testing in extreme temperatures.

Test of satellite componentsBasic research: The basis for medical innovation

Researchers involved in basic research are curious: They want to trace the mechanisms that drive complex processes in nature, and do so in an unbiased, systematic and accurate way. They create the basis for new machines and procedures in all scientific disciplines. However, often the valuable contribution from the research institutions is only apparent in retrospect.

Basis researchTemperature control solutions in the semiconductor industry

Every modern smartphone has a million times more computing power than what was available to NASA for the Apollo missions. We have the semiconductor industry to thank for this, as it works to accommodate more and more power in less and less space, pushing the limits of what is technically and physically possible. Complex circuits, which can’t even be recognized except with strong magnification, are assembled using highly precise procedures. In the semiconductor industry there is quite literally very little room for error. Numerous procedural steps are linked to absolutely precise temperature control.

Temperature control solutions in the semiconductor industry

Temperature control in the chemical industry

As a supplier to almost all manufacturing sectors, the chemicals industry requires efficient and safe processes to cover the needs of production. Because most chemical reactions are either exothermic (release heat) or endothermic (heat is absorbed), hassle-free temperature control is of vital importance to the chemical industry. In particular for process technology, the precise and constant temperature control of individual process steps is a critical issue. The use of temperature control solutions in process technology ranges from the laboratory scale in development of new materials and procedures to the temperature control of large-scale industrial production.

Chemical process technologyTemperature control systems in the food industry

An uninterrupted cooling chain, sufficiently high temperature during processing or constant temperature during the fermentation processes: Temperature is obviously an essential component during many processes in the food industry. In addition to the obvious uses there are also numerous other processes in which temperature is important. These range from testing and calibration of flow sensors to preconditioning (pre-temperature controlling) of individual ingredients in the development of new recipes or consistent temperatures in water baths. Without precise temperature management in production and processing operations, chocolate, for example, would lose everything that we love about it.

Temperature control in the food industryTemperature Control of Yeast Dough Samples