Temperature Control of Yeast Dough Samples

Modern food manufacturers now often produce dough products, such as frozen pizzas, which should not only taste good but also be healthier, longer-lasting, and of better quality.

Exact quality standards, strictly regulated production plans, changing preferences - food producers are confronted with a wide range of requirements. The associated control procedures are often very time-consuming.

In cooperation with Nestlé's research center, Dr. Helmut Trautmann from abiotec AG has developed a special gas volume bath monitor for pizza dough samples, which can be used to measure quality and gas formation precisely and quickly.

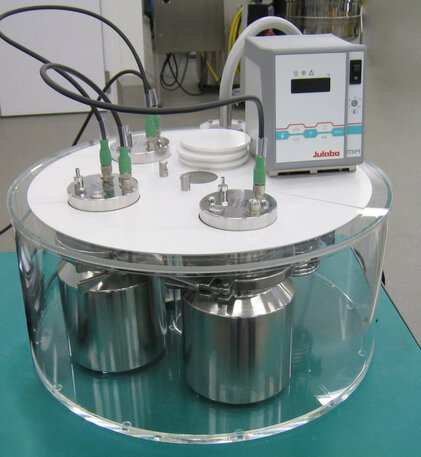

The gas volume special bath monitor consists of a large Plexiglas bath, a JULABO MA heating immersion circulator from the TopTech series, and the JULABO FT200 immersion cooler with immersion probe, which is used for rapid cooling of liquids to low temperatures, and here especially for counter-cooling of the heating immersion circulator. The measuring principle is carried out in closed measuring units using a long-term stable and precise absolute pressure measurement.

Analysis of Conventional Pizza Dough

Pizza dough consists of the main ingredients flour, water, and CO2. The dough forms spontaneously when a suspension of flour and water reacts. Microorganisms present in the air - mainly yeasts - colonize the dough. These yeasts are unicellular fungi that multiply by sprouting. As a result of their metabolism (fermentation), carbon dioxide (CO2) is produced as an end product [1].

Development test series were carried out for the development of ready-made pizza dough preparations - which can now be found in the refrigerated shelves of every supermarket - which analyzed various yeast strains as well as dough recipes, and their gas formation processes.

[1]Source: https://wissensforum-backwaren.de/wp-content/uploads/kap_VI-2_Teiglockerung_Hefeteig.pdf - S.VI-2.1:Biologische Teiglockerung – Hefeteig

[2]Source: https://www.gesundheitsindustrie-bw.de/de/fachbeitrag/aktuell/verstehen-was-im-teig-passiert/

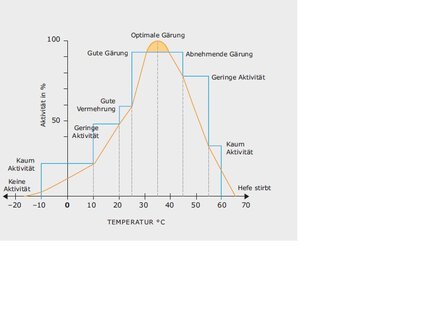

Temperature-dependent Fermentation

Like all biochemical reactions, the fermentation reactions of the pizza dough are temperature-dependent. The yeast activity and thus the fermentation time is a function of the temperature and the amount of yeast. The reaction rate of fermentation increases typically exponentially with increasing temperature. With increasing temperature, the yeast activity also increases up to an optimum fermentation temperature of about +35 °C to drop steeply again [3]. For conventional pizza dough, the following applies for temperatures up to +35 °C: the warmer it is, the faster the gas formation takes place.

Higher temperatures slow down and damage the cellular enzymolysis of yeast cells. The fermentation force decreases and comes to a complete standstill at temperatures around +65 °C due to the coagulation of the cell protein [4].

However, if the temperature drops below +30 °C to the freezing point, the fermentation intensity is also increasingly reduced. Below 0 °C, the yeast is only slightly active. Their ingredients (mineral salts, sugar, soluble protein) cause a lowering of the freezing point of the cell water, so that yeast cells usually do not freeze until -7 °C. The yeast withstands frost temperatures of around -20 °C for months without significant damage to the fermentation force. It also survives repeated freezing and thawing without any major impairment of its activity [5].

Under cooled conditions, yeasts develop their gas-forming activity very slowly and over several weeks. Compared to heated conditions, these activities are reduced by orders of magnitude [6]. The gas formation processes from the dough sample tests show the initially moderate and later clearly increasing gas formation activity on the gas volume special bath monitor. Accordingly, longer shelf life is guaranteed for the cooled pizza dough, i.e., the cooler the dough sample, the longer the shelf life.

[3]Source: https://wissensforum-backwaren.de/wp-content/uploads/20_Die-Gaersteuerung-mittels-Kaeltetechnik_Fachbroschuere.pdf -Die Gärsteuerung mittels Kältetechnik, S.12

[4]Source: https://wissensforum-backwaren.de/wp-content/uploads/20_Die-Gaersteuerung-mittels-Kaeltetechnik_Fachbroschuere.pdf -Die Gärsteuerung mittels Kältetechnik, S.28

[5]Source: https://wissensforum-backwaren.de/wp-content/uploads/20_Die-Gaersteuerung-mittels-Kaeltetechnik_Fachbroschuere.pdf -Die Gärsteuerung mittels Kältetechnik, S.29

[6]Source: https://www.gesundheitsindustrie-bw.de/de/fachbeitrag/aktuell/verstehen-was-im-teig-passiert/

Precise and Trouble-free Measurement Technology / Fermentation Process Control with Heat Technology

The greatest challenge in measuring dough quality is determining the gas formation of dissolved CO2, which manifests itself in the expansion of the dough volume.

The gas volume (special bath) monitor was developed for the precise and reliable evaluation of the dough volume: The measuring principle is carried out in closed measuring units using a long-term stable and precise absolute pressure measurement [7]. The device determines the gas quantities formed based on the General Gas Equation (p* V=n*R*T).

Minimum pressure changes are recorded during the test sequence. These serve as the basis for calculating the gas volumes formed. If a definable pressure threshold value is exceeded, a short-term pressure equalization with the environment is carried out via a solenoid valve, and the measuring unit is immediately closed again, and the integrating measurement is consistently continued. Due to the precise and temporally high-resolution recording of the gas formation and its derived quantities, the quality assurance, as well as subsequent follow-up checks, can be reduced from one to two hours each to about half an hour. At the same time, the new additional parameters allow access to extended quality attributes and also improve safety in the assessment of yeast batches [8].

[7]Source: http://www.abiotec.ch/downloads/d_Gasvolumen_Monitor.pdf

[8]Source: https://www.gesundheitsindustrie-bw.de/de/fachbeitrag/aktuell/verstehen-was-im-teig-passiert/

Conclusion:

In summary, it can be said that the gas volume (special bath) monitor can measure the meticulous characteristics of the pizza dough accurately and trouble-free even over long periods or large gas volumes - regardless of location and environmental influences.

The precise determination of gas formation rates over a wide measuring range (> four powers of ten, i.e., from 1 ml per day to approx. 3 l per hour) ensures optimum routine measurements in the quality assurance of pizza dough samples [9].

The gas volume special bath monitor is a precision device that can control and meticulously record them, especially for the development of new dough recipes and products. It is a robust but highly accurate measuring device that meets the constantly changing preferences and requirements of the market.

All biochemical reactions associated with a corresponding gas formation or gas consumption reaction can thus be recorded very sensitively and quickly. Even purely physical effects based on gas absorption or desorption phenomena can be determined using the gas volume (special bath) monitor. In addition to its application in food technology, the highly sensitive measuring device can also be optimally used for demanding tasks and questions in the pharmaceutical and environmental technology sectors, including biogas production.

[9]Source: http://www.abiotec.ch/downloads/d_Gasvolumen_Monitor.pdf

Technical Data - Specifications

The gas volume special bath monitor is designed for temperature-controlled conditions (water bath, incubator, cold store) from 0° C to approx. +45° C and for small dough quantities in the range between 10 and 200 grams. Upon request, receptacles for significantly larger sample quantities are also available.

Wide measuring range over 4 powers of ten:

1 ml per day up to approx. 3 liters per hour

High resolution

0.05 to 0.2 ml gas (850 ml or 2.5l vessel)

The measuring heads are made of stainless steel, in a water-protected design with the following functions integrated into the housing:

• Precision absolute pressure sensor 0.6 to 1.6 bar

• High-resolution, long-term stable, temperature-compensated calibration

• Transmitter electronics with RS-485 interface

• Special electromagnetic valve with minimum leakage rate

• Multi-level overpressure safety concept (hardware- and software-based)

• Measuring vessels in various dimensions

• Standard volumes: 850 ml and 2.5 l (custom-made)

• Tri-Clamp sealing technology with a special gas-tight seal

• Pressure approval up to 8 or 10 bar

Specifications of the JULABO MA Heating Immersion Circulator

JULABO heating immersion circulators of the TopTech series are used worldwide and form the basis of the JULABO circulator portfolio. Whether in research, material testing, or technical systems – the well-proven and reliable technology is valued by users in all industries worldwide.

The JULABO MA heating immersion circulator from the TopTech series is equipped with a bath attachment clamp for wall thicknesses of up to 26 mm, whereby the clamp allows quick and easy installation on existing bath tanks. Alternatively, it can also be attached to a laboratory stand. The immersion components are made of high-quality stainless steel or plastic and achieve an immersion depth of 16.5 cm (can be reduced to 14.5 cm). The pump set available as an accessory enables external temperature applications. In addition, an add-on cooling coil for cooling water connection is available for temperature control applications close to or below the ambient temperature.

The JULABO MA heating immersion circulator is equipped with a large MULTI-DISPLAY (LED) that is easily visible from a distance. In addition, warning/safety functions, high temperature cut-off, and electronically adjustable pump output stages

(display resolution 0.01/0.1 °C) can be viewed and called up via a comfort control panel. For maximum application safety, the visual and audible warning enables the system to be shut off in good time in an emergency.

In addition, the device scores with high-precision PID2 temperature control with disturbance compensation and adjustable control parameters (stability ±0.01...±0.02 °C). The Absolute Temperature Calibration offers the highest measuring accuracy to compensate for a physically caused temperature difference and 3-point calibration. The JULABO MA heating immersion circulators are equipped with SMART PUMP, the reliable, electronically adjustable pump output stages. The serial connection of an RS232 interface to the PC enables data communication.

Advantages of JULABO Immersion Coolers

JULABO immersion coolers are a budget-priced and space-saving alternative to conventional cooling with tap water, i.e., unnecessary cooling water consumption is avoided on a small footprint. Due to its straightforward operation and handling, this device series is recommended for a wide range of cooling tasks.

Fig.: Gas volume special bath monitor with JULABO MA heating immersion circulator of the TopTech series and JULABO FT200 immersion cooler

Fig.: Gas volume special bath monitor with JULABO MA heating immersion circulator of the TopTech series