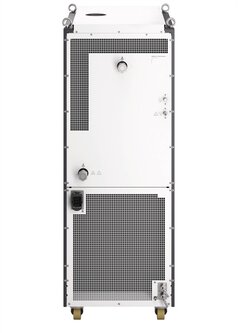

PRESTO W56 Process system

The most powerful, single-stage, highly dynamic temperature control systems

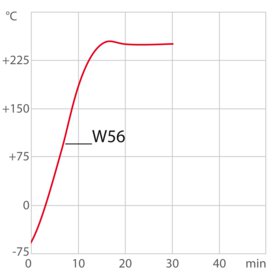

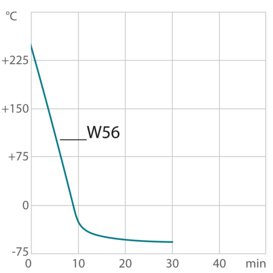

The water-cooled PRESTO W56 is able to quickly and efficiently control the temperature in applications requiring a great deal of power. Even at low temperatures, this model has large power reserves for demanding external applications.

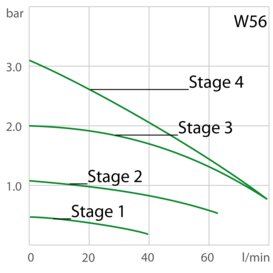

The magnetically coupled pump allows the user to optimally adjust pump capacity to suit the application, even over large distances and height differences, as well as for pressure-sensitive applications. Use of the latest thermodynamic technologies means that the cooling capacity is automatically adjusted to the current power requirements. In combination with additional optimizations, this makes the PRESTO W56 very economical and energy-efficient.

PRESTO W56 Benefits

100% Checked.

100% testing. 100% quality. Each JULABO Circulator undergoes thorough quality testing before leaving the factory.

Green technology.

Development consistently applied environmentally friendly materials and technologies.

Touch display. Perfect operation.

With the touch display, the user always has an overview of all values and functions. The intuitive and multilingual menu structure enables perfect control.

Convenience for several users

Administrator level for customizing instrument settings, user levels with limited permissions for fast and safe defined access, password protection, all levels adjustable