PRESTO A80 Process system

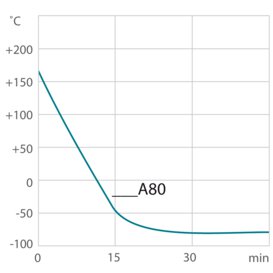

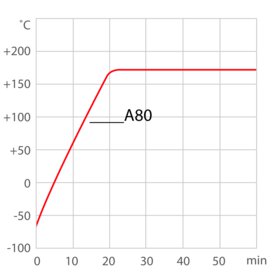

2-stage process circulators for low temperatures

As air- or water-cooled versions, the units with 2-stage refrigeration unit offer high cooling and heating capacities for lowest temperatures down to -80 °C.

The highly dynamic temperature control systems PRESTO are designed for high-precision temperature control for a wide range of applications such as reactor vessels or material stress tests. Moreover, by using efficient components, the process systems can compensate exothermic and endothermic reactions exceptionally fast. Permanent internal monitoring and self-lubricating pumps ensure a long life-time. In addition, numerous interfaces offer many remote control possibilities across networks or for integration into higher-level control systems.

PRESTO A80 Benefits

Touch display. Perfect operation.

With the touch display, the user always has an overview of all values and functions. The intuitive and multilingual menu structure enables perfect control.

Convenience for several users

Administrator level for customizing instrument settings, user levels with limited permissions for fast and safe defined access, password protection, all levels adjustable

100 % Cooling capacity

‘Active Cooling Control’ for cooling available throughout the entire working temperature range, fast cool-down even at higher temperatures

Intelligent temperature control.

Intelligent cascade control - automatic and self-optimizing adaptation of the PID control parameters with external stability of +/- 0.05 °C.